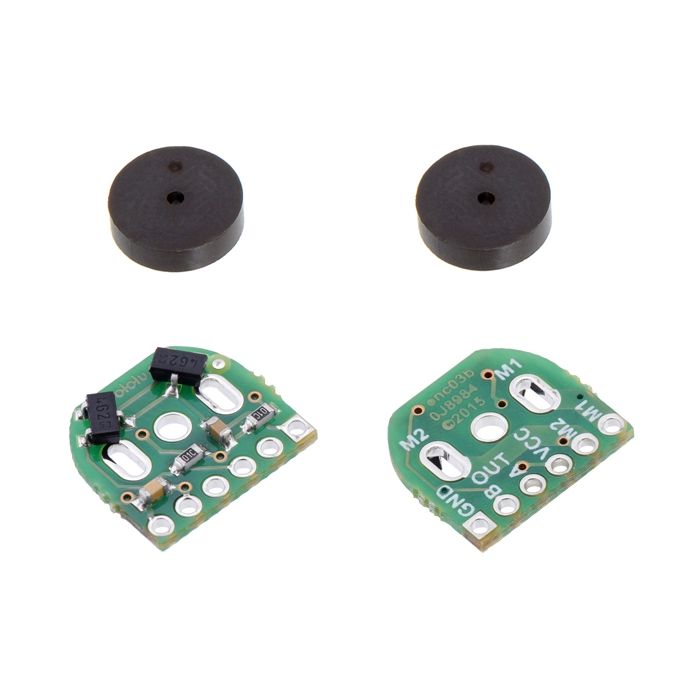

Magnetic Encoder Pair Kit for Micro Metal Gearmotors, 12 CPR, 2.7-18V (HPCB compatible)

In stock, ships same business day if ordered before 2PM

Delivered by Tue, 3rd of Mar

Quantity Discounts:

- 10+ $14.57 (exc GST)

- 25+ $14.12 (exc GST)

Newer versions available: Pololu now have versions of this encoder with top-entry connectors or side-entry connectors that work with Pololu's corresponding removable JST SH-type cables of various lengths.

|

Side-by-side comparison of Magnetic Encoder with Top-Entry Connector (left), Side-Entry Connector (center), and 2mm-pitch through-holes (right). |

|---|

This kit includes two dual-channel Hall effect sensor boards and two 6-pole magnetic discs that can be used to add quadrature encoding to two micro metal gearmotors with extended back shafts (motors are not included with this kit). The encoder board senses the rotation of the magnetic disc and provides a resolution of 12 counts per revolution of the motor shaft when counting both edges of both channels. To compute the counts per revolution of the gearbox output shaft, multiply the gear ratio by 12.

|

This compact encoder solution fits within the 12 mm × 10 mm cross section of the motors on three of the four sides, and it only extends 0.6 mm past the edge of the fourth side (note: if you need it to be flush with that last side, you can carefully grind the board down a little and solder to the remaining half-holes). The assembly does not extend past the end of the extended motor shaft, which protrudes 5 mm beyond the plastic end cap on the back of the motor.

|

|

Note: This sensor system is intended for users comfortable with the physical encoder installation. It only works with micro metal gearmotors that have extended back shafts.

Pinout and installation

The encoder board is designed to be soldered directly to the back of the motor, with the back shaft of the motor protruding through the hole in the middle of the circuit board. One way to achieve good alignment between the board and the motor is to tack down the board to one motor pin and to solder the other pin only when the board is flat and well aligned. Be careful to avoid prolonged heating of the motor pins, which could deform the plastic end cap of the motor or the motor brushes. Once the board is soldered down to the two terminals, the motor leads are connected to the M1 and M2 pads along the edge of the board; the remaining four pads are used to power the sensors and access the two quadrature outputs:

|

|

The sensors are powered through the VCC and GND pins. VCC can be 2.7 V to 18 V, and the quadrature outputs A and B are digital signals that are either driven low (0 V) by the sensors or pulled to VCC through 10 kO pull-up resistors, depending on the applied magnetic field. The sensors’ comparators have built-in hysteresis, which prevents spurious signals in cases where the motor stops near a transition point.

|

Encoder A and B outputs of a magnetic encoder on a high-power (HP) micro metal gearmotor running at 6 V. |

|---|

The board’s six pads have a 2 mm pitch, so Pololu do not work with common 0.1" connectors. One option for connecting to the board is to solder in individual wires, such as in the example below:

|

Alternatively, you can solder a 2mm-pitch connector to the board. The examples below show a male header, which gives you the option of making a detachable cable terminated by a 6-pin 2mm-pitch female header. If the pins are angled over the motor, as shown in the picture below, they will just barely protrude through the holes in the board. Note that in this orientation, there is room to plug in a female header even when Pololu's extended micro metal gearmotor bracket is being used.

|

If the pins are pointed away from the motor, they will need to be angled so that they sufficiently clear the magnetic disc. With a decent soldering iron, it is possible to solder them in this orientation even after the encoder has been installed on the motor.

|

Once the board is soldered to the motor, the magnetic encoder disc can be pushed onto the motor shaft. One easy way to accomplish this is to press the motor onto the disc while it is sitting on a flat surface, pushing until the shaft makes contact with that surface. The size of the gap between the encoder disc and the sensor board does not have a big impact on performance as long as the motor shaft is at least all the way through the disc.

Schematic diagram

|

This schematic is also available as a downloadable pdf (125k pdf).

Comparison to previous version

This encoder version is a minor alteration to the previous version that just enlarges the motor terminal holes so Pololu can accommodate the larger terminals on the HPCB versions of Pololu's micro metal gearmotors. The two encoder versions are otherwise identical, and this new one can serve as a drop-in replacement for the previous one. The following two pictures show a side-by-side comparison of the old version (left) and the new one (right):

|

|

People often buy this product together with:

| TB6612FNG Dual Motor Driver Carrier |

| Pololu Micro Metal Gearmotor Bracket Pair - Black |

| Pololu Micro Metal Gearmotor Bracket Extended Pair |

Dimensions

| Size: | 10.6 mm × 11.6 mm1 |

|---|---|

| Weight: | 1.0 g2 |

General specifications

| Minimum operating voltage: | 2.7 V |

|---|---|

| Maximum operating voltage: | 18 V |

| Connector: | none (2mm-pitch through-holes) |

Identifying markings

| PCB dev codes: | enc03b |

|---|---|

| Other PCB markings: | 0J8984 |

Notes:

- 1

- The assembled encoder will extend 5 mm beyond the plastic motor end cap (it fits entirely within the length of the extended motor shaft).

- 2

- Weight of full set. Each encoder board weighs ~0.2 g and each magnet disc weighs ~0.3 g.

File downloads

-

Magnetic Encoder Kit for Micro Metal Gearmotors schematic diagram (125k pdf)

-

3D models of Magnetic Encoder Pair Kit for Micro Metal Gearmotors, 12 CPR, 2.7-18V (HPCB compatible) (585k zip)

This file contains 3D models (in the step file format) of the components for the Magnetic Encoder Pair Kit for Micro Metal Gearmotors, 12 CPR, 2.7-18V (HPCB compatible)

-

Drill guide for the enc03b encoder PCB (25k dxf)

This DXF drawing shows the locations of all of the board’s holes.

This product is listed in:

Sensors>EncodersComponents & Parts>Motors>Metal Gearmotors>Mounting & Accessories

Exact shipping can be calculated on the view cart page (no login required).

Products that weigh more than 0.5 KG may cost more than what's shown (for example, test equipment, machines, >500mL liquids, etc).

We deliver Australia-wide with these options (depends on the final destination - you can get a quote on the view cart page):

- $3+ for Stamped Mail (typically 10+ business days, not tracked, only available on selected small items)

- $7+ for Standard Post (typically 6+ business days, tracked)

- $11+ for Express Post (typically 2+ business days, tracked)

- Pickup - Free! Only available to customers who live in the Newcastle region (must order online and only pickup after we email to notify you the order is ready). Orders placed after 2PM may not be ready until the following business day.

Non-metro addresses in WA, NT, SA & TAS can take 2+ days in addition to the above information.

Some batteries (such as LiPo) can't be shipped by Air. During checkout, Express Post and International Methods will not be an option if you have that type of battery in your shopping cart.

International Orders - the following rates are for New Zealand and will vary for other countries:

- $12+ for Pack and Track (3+ days, tracked)

- $16+ for Express International (2-5 days, tracked)

If you order lots of gear, the postage amount will increase based on the weight of your order.

Our physical address (here's a PDF which includes other key business details):

40 Aruma Place

Cardiff

NSW, 2285

Australia

Take a look at our customer service page if you have other questions such as "do we do purchase orders" (yes!) or "are prices GST inclusive" (yes they are!). We're here to help - get in touch with us to talk shop.

Have a product question? We're here to help!

Videos

View AllGuides

Servos, Steppers or Solenoids? | Choosing an Actuator to Move Your Project

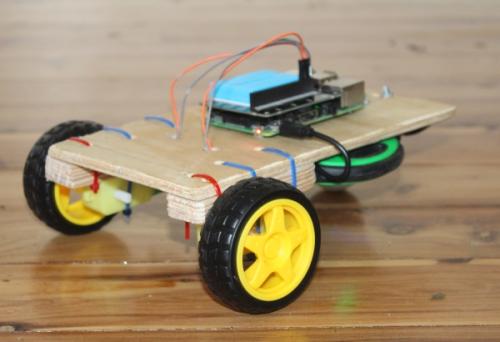

How To Control A Motor with the Raspberry Pi

The Maker Revolution

Motor Drivers vs. Motor Controllers

Projects

WhyzaGC - Feather ESP32 addon to the MightyOhm Gieger Counter

DIY Pi Buggy

Makers love reviews as much as you do, please follow this link to review the products you have purchased.

Product Comments