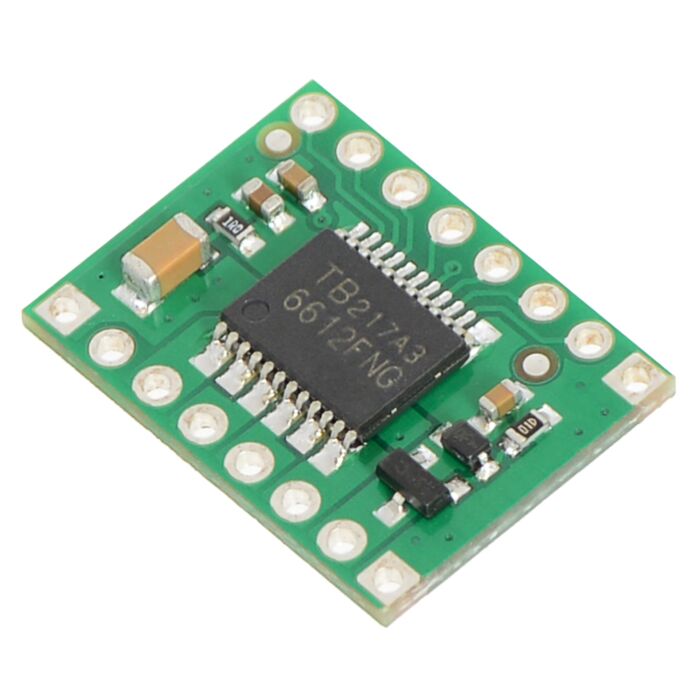

TB6612FNG Dual Motor Driver Carrier

In stock, ships same business day if ordered before 2PM

Delivered by Tue, 10th of Mar

Quantity Discounts:

- 10+ $7.20 (exc GST)

- 25+ $6.97 (exc GST)

|

The TB6612FNG (308k pdf) is a great dual motor driver that is perfect for interfacing two small DC motors such as Pololu's micro metal gearmotors to a microcontroller, and it can also be used to control a single bipolar stepper motor. The MOSFET-based H-bridges are much more efficient than the BJT-based H-bridges used in older drivers such as the L298N and Sanyo’s LB1836M, which allows more current to be delivered to the motors and less to be drawn from the logic supply (the LB1836 still has the TB6612 beat for really low-voltage applications). Pololu's little breakout board gives you direct access to all of the features of the TB6612FNG and adds power supply capacitors and reverse battery protection on the motor supply (note: there is no reverse protection on the Vcc connection).

|

In a typical application, power connections are made on one side of the board and control connections are made on the other. All of the control inputs are internally pulled low. Each of the two motor channels has two direction control pins and a speed control pin that accepts a PWM input with a frequency of up to 100 kHz. The STBY pin must be driven high to take the driver out of standby mode.

|

TB6612FNG dual motor driver carrier on a breadboard. |

|---|

The distance between the header rows on the PCB is 0.1" smaller than a standard 0.6" DIP package (e.g. the Baby Orangutan), but the pin spacing allows it to conveniently fit in 0.1" breadboards and perfboards.

For a more advanced motor controller based on this driver, please consider the qik 2s9v1 dual serial motor controller. For a robot controller based on this driver, please consider the Baby Orangutan, Orangutan SV-328, Orangutan SVP-1284, and 3pi robot, which connect the TB6612 to a user-programmable AVR microcontroller. For a similar motor driver that is easy to use with Arduinos, consider Pololu's DRV8835 dual motor driver shield, and for a similar motor driver with a much higher maximum operating voltage, consider Pololu's A4990 dual motor driver carrier.

Features and specifications

- Dual-H-bridge motor driver: can drive two DC motors or one bipolar stepper motor

- Recommended motor voltage (VMOT): 4.5 V to 13.5 V (can operate down to 2.5 V with derated performance)

- Logic voltage (VCC): 2.7 V to 5.5 V

- Output current maximum: 3 A per channel

- Output current continuous: 1 A per channel (can be paralleled to deliver 2 A continuous)

- Maximum PWM frequency: 100 kHz

- Built-in thermal shutdown circuit

- Filtering capacitors on both supply lines

- Reverse-power protection on the motor supply

Real-world power dissipation considerations

The TB6612 motor driver used on the carrier board has a peak current rating of 3 A per channel. The peak ratings are for quick transients (e.g. when a motor is first turned on), and the continuous rating of 1 A is dependent on various conditions, such as the ambient temperature. The actual current you can deliver will depend on how well you can keep the motor driver cool. The carrier’s printed circuit board is designed to draw heat out of the motor driver chip, but performance can be improved by adding a heat sink.

This product can get hot enough to burn you long before the chip overheats. Take care when handling this product and other components connected to it.

Included hardware

A 1×16-pin breakaway 0.1" male header strip is included with the TB6612FNG motor driver carrier. This strip can optionally be soldered to the carrier board so that it can be used with perfboards, solderless breadboards, or 0.1" female connectors. (The headers might ship as two 1×8 pieces or as a single 1×16 piece that can be broken in half.)

|

Schematic diagram

|

This schematic is also available as a downloadable pdf (85k pdf).

People often buy this product together with:

| Pololu Ball Caster with 3/8" Metal Ball |

| QTR-8A Reflectance Sensor Array |

| Pololu Micro Metal Gearmotor Bracket Pair - Black |

Dimensions

| Size: | 0.60" x 0.80" |

|---|---|

| Weight: | 1.5 g |

General specifications

| Motor driver: | TB6612FNG |

|---|---|

| Motor channels: | 2 |

| Minimum operating voltage: | 4.5 V1 |

| Maximum operating voltage: | 13.5 V |

| Continuous output current per channel: | 1 A |

| Peak output current per channel: | 3 A |

| Continuous paralleled output current: | 2 A |

| Maximum PWM frequency: | 100 kHz |

| Minimum logic voltage: | 2.7 V |

| Maximum logic voltage: | 5.5 V |

| Reverse voltage protection?: | Y |

Notes:

Documentation and other information

-

Application Note: Using the Motor Driver on the 3pi Robot and Orangutan Robot Controllers (Printable PDF)

Detailed information about the 3pi Robot, Orangutan SV-328/168 and LV-168, and Baby Orangutan B motor drivers, including truth tables and sample code.

File downloads

-

TB6612FNG-dual motor driver carrier schematic diagram (85k pdf)

Printable schematic diagram for the TB6612FNG-dual motor driver carrier.

-

Toshiba TB6612FNG motor driver datasheet (308k pdf)

-

Dimension diagram of the TB6612FNG Dual Motor Driver Carrier (220k pdf)

-

3D model of the TB6612FNG Dual Motor Driver Carrier (4MB step)

-

Drill guide for the TB6612FNG Dual Motor Driver Carrier (29k dxf)

This DXF drawing shows the locations of all of the board’s holes.

Exact shipping can be calculated on the view cart page (no login required).

Products that weigh more than 0.5 KG may cost more than what's shown (for example, test equipment, machines, >500mL liquids, etc).

We deliver Australia-wide with these options (depends on the final destination - you can get a quote on the view cart page):

- $3+ for Stamped Mail (typically 10+ business days, not tracked, only available on selected small items)

- $7+ for Standard Post (typically 6+ business days, tracked)

- $11+ for Express Post (typically 2+ business days, tracked)

- Pickup - Free! Only available to customers who live in the Newcastle region (must order online and only pickup after we email to notify you the order is ready). Orders placed after 2PM may not be ready until the following business day.

Non-metro addresses in WA, NT, SA & TAS can take 2+ days in addition to the above information.

Some batteries (such as LiPo) can't be shipped by Air. During checkout, Express Post and International Methods will not be an option if you have that type of battery in your shopping cart.

International Orders - the following rates are for New Zealand and will vary for other countries:

- $12+ for Pack and Track (3+ days, tracked)

- $16+ for Express International (2-5 days, tracked)

If you order lots of gear, the postage amount will increase based on the weight of your order.

Our physical address (here's a PDF which includes other key business details):

40 Aruma Place

Cardiff

NSW, 2285

Australia

Take a look at our customer service page if you have other questions such as "do we do purchase orders" (yes!) or "are prices GST inclusive" (yes they are!). We're here to help - get in touch with us to talk shop.

Have a product question? We're here to help!

Videos

View AllGuides

The Maker Revolution

Motor Drivers vs. Motor Controllers

Projects

Raspberry Pi Cyberdeck (SDR Edition)

Pico-Dog Motion Activated Audio Alarm

WaveJumper: Music Sample Slicer on a Breadboard

Makers love reviews as much as you do, please follow this link to review the products you have purchased.

Product Comments