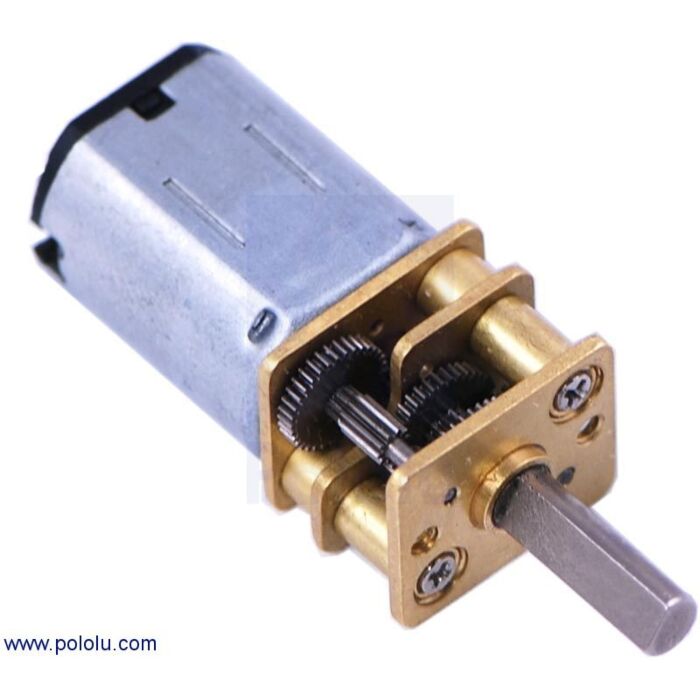

250:1 Micro Metal Gearmotor (Low Power)

Available with a lead time

Expect dispatch between Feb 23 and Feb 26

Quantity Discounts:

- 10+ $35.00 (exc GST)

- 25+ $33.90 (exc GST)

These tiny brushed DC gearmotors are available in a wide range of gear ratios—from 5:1 up to 1000:1—and with five different motors: high-power 6 V and 12 V motors with long-life carbon brushes (HPCB), and high-power (HP), medium power (MP), and low power (LP) 6 V motors with shorter-life precious metal brushes. The 6 V and 12 V HPCB motors offer the same performance at their respective nominal voltages, just with the 12 V motor drawing half the current of the 6 V motor. The 6 V HPCB and 6 V HP motors are identical except for their brushes, which only affect the lifetime of the motor.

The HPCB versions (shown on the left in the picture below) can be differentiated from versions with precious metal brushes (shown on the right) by their copper-colored terminals. Note that the HPCB terminals are 0.5 mm wider than those on the other micro metal gearmotor versions (2 mm vs. 1.5 mm), and they are about 1 mm closer together (6 mm vs. 7 mm).

|

|

|

Versions of these gearmotors are also available with an additional 1 mm-diameter output shaft that protrudes from the rear of the motor. This 4.5 mm-long rear shaft rotates at the same speed as the input to the gearbox and offers a way to add an encoder, such as Pololu's encoders for micro metal gearmotors (see the picture on the right), to provide motor speed or position feedback.

With the exception of the 1000:1 gear ratio versions, all of the micro metal gearmotors have the same physical dimensions, so one version can be easily swapped for another if your design requirements change.

Please see the micro metal gearmotor datasheet (5MB pdf) for more information, including detailed performance graphs for each micro metal gearmotor version. You can also use Pololu's dynamically sortable micro metal gearmotor comparison table to search for the gearmotor that offers the best combination of speed, torque, and current draw for your particular application. A more basic comparison table is available below.

Note: Stalling or overloading gearmotors can greatly decrease their lifetimes and even result in immediate damage. The recommended upper limit for instantaneous torque is 2.5 kg-cm (35 oz-in) for the 380:1 and 1000:1 gearboxes, and 2 kg-cm (25 oz-in) for all the other gear ratios; Pololu strongly advise keeping applied loads well under this limit. Stalls can also result in rapid (potentially on the order of seconds) thermal damage to the motor windings and brushes, especially for the versions that use high-power (HP and HPCB) motors; a general recommendation for brushed DC motor operation is 25% or less of the stall current.

In general, these kinds of motors can run at voltages above and below their nominal voltages; lower voltages might not be practical, and higher voltages could start negatively affecting the life of the motor.

Details for item #1095

Exact gear ratio:

This gearmotor is a miniature low-power, 6 V brushed DC motor with a 248.98:1 metal gearbox. It has a cross section of 10 × 12 mm, and the D-shaped gearbox output shaft is 9 mm long and 3 mm in diameter.

Key specifications:

| voltage | no-load performance | stall extrapolation |

|---|---|---|

| 6 V | 54 RPM, 40 mA | 1.7 kg·cm (24 oz·in), 0.36 A |

Gearmotor Dimensions

In terms of size, these gearmotors are very similar to Sanyo’s popular 12 mm NA4S DC gearmotors, and gearmotors with this form factor are occasionally referred to as N20 motors. The versions with carbon brushes (HPCB) have slightly different terminal and end-cap dimensions than the versions with precious metal brushes, but all of the other dimensions are identical.

Dimensions of versions with carbon brushes (HPCB)

|

Dimensions of the Pololu micro metal gearmotors with carbon brushes (HPCB). Units are mm over [inches]. |

|---|

Dimensions of versions with precious metal brushes (LP, MP, and HP)

|

Dimensions of the Pololu micro metal gearmotors with precious metal brushes: low-power (LP), medium-power (MP), and high-power (HP). Units are mm over [inches]. |

|---|

These diagrams are also available as a downloadable PDF (262k pdf).

Motor Accessories

- Wheels and hubs: The micro metal gearmotor’s output shaft matches Pololu's assortment of Pololu wheels and the Solarbotics RW2i rubber wheel. You can also use Pololu's Pololu universal mounting hubs to mount custom wheels and mechanism to the micro metal gearmotor’s output shaft, and you can use Pololu's 12mm hex wheel adapter to use this motor with many common hobby RC wheels.

|

|

|

|

12mm Hex Wheel Adapter for 3mm Shaft on a Micro Metal Gearmotor. |

|---|

- Mounting brackets: Pololu's mounting bracket (also available in white) and extended mounting bracket are specifically designed to securely mount the gearmotor while enclosing the exposed gears. Pololu recommend the extended mounting bracket for wheels with recessed hubs, such as the Pololu wheel 42×19mm. Pololu's micro metal gearmotors will also work with Pololu's 15.5D mm metal gearmotor bracket pair.

- Quadrature encoders: Pololu offer several quadrature encoders that work with Pololu's micro metal gearmotors.

|

|

Note: The HPCB versions of Pololu's micro metal gearmotors are not compatible with Pololu's #2590 and #2591 optical encoders or Pololu's older #2598 magnetic encoders (the terminals are too wide to fit through the corresponding holes in the encoder boards). However, they are compatible with Pololu's newer #3081, #4760, and #4761 magnetic encoders.

- Motor controllers and drivers: Pololu have a number of motor controllers, motor drivers, and robot controllers that make it easy to drive these micro metal gearmotors. For the 6 V micro metal gearmotors, consider the DRV8838 single-channel motor driver carrier, the DRV8833 dual motor driver carrier, and DRV8835 dual motor driver carrier (or DRV8835 shield for Arduino). For the 12 V micro metal gearmotors, consider the MAX14870 single-channel motor driver carrier, DRV8801 single-channel motor driver carrier, and A4990 dual motor driver carrier (or A4990 shield for Arduino).

|

|

|

- Current sensors: Pololu have an assortment of Hall effect-based current sensors to choose from for those who need to monitor motor current:

|

|

Pololu also incorporate these motors into some of Pololu's products, including Pololu's Zumo robot and 3pi robot :

|

|

Selecting the Right Gearmotor

Pololu offer a wide selection of metal gearmotors that offer different combinations of speed and torque. Pololu's metal gearmotor comparison table can help you find the motor that best meets your project’s requirements.

|

People often buy this product together with:

| Pololu Micro Metal Gearmotor Bracket Pair - Black |

| 100:1 Micro Metal Gearmotor LP 6V |

| 298:1 Micro Metal Gearmotor LP 6V |

Dimensions

| Size: | 10 × 12 × 26 mm1 |

|---|---|

| Weight: | 9.5 oz |

| Shaft diameter: | 3 mm2 |

General specifications

| Gear ratio: | 248.98:1 |

|---|---|

| No-load speed @ 6V: | 54 rpm3 |

| No-load current @ 6V: | 0.04 A4 |

| Stall current @ 6V: | 0.36 A |

| Stall torque @ 6V: | 1.7 kg·cm |

| Max output power @ 6V: | 0.23 W |

| Extended motor shaft?: | N |

| Motor type: | 0.36A stall @ 6V (LP 6V) |

Performance at maximum efficiency

| Max efficiency @ 6V: | 26 % |

|---|---|

| Speed at max efficiency: | 39 rpm |

| Torque at max efficiency: | 0.42 kg·cm |

| Current at max efficiency: | 0.11 A |

| Output power at max efficiency: | 0.17 W |

Notes:

- 1

- Output shaft adds 9 mm to the 26 mm length.

- 2

- D shaft.

- 3

- Typical; ±20%.

- 4

- Typical, ±50%; no-load current depends on internal friction, which is affected by many factors, including ambient temperature and duration of motor operation.

File downloads

-

Dimension diagrams of Pololu Micro Metal Gearmotors (262k pdf)

-

3D model of a Micro Metal Gearmotor with Extended Motor Shaft and a #1086 bracket (4MB step)

3D model of a Micro Metal Gearmotor with Extended Motor Shaft and a #1086 bracket (or #989 bracket, which is just a black version of the #1086).

-

3D model of a Micro Metal Gearmotor and a #1086 bracket (4MB step)

3D model of a Micro Metal Gearmotor and a #1086 bracket (or #989 bracket, which is just a black version of the #1086).

-

3D model of Micro Metal Gearmotors (single-shaft, precious metal brushes, not 1000:1) (11MB step)

3D model of low-power, medium-power, high-power Pololu Micro Metal Gearmotors. This diagram does not apply to the HPCB versions, dual-shaft versions, or 1000:1 gear ratios.

-

3D model of Micro Metal Gearmotors with extended motor shafts (precious metal brushes, not 1000:1) (11MB step)

3D model of low-power, medium-power, high-power Pololu Micro Metal Gearmotors with extended motor shafts. This diagram does not apply to the HPCB versions, single-shaft versions, or 1000:1 gear ratios.

-

3D model of 1000:1 Micro Metal Gearmotors (single-shaft, precious metal brushes) (14MB step)

3D model of Pololu Micro Metal Gearmotors with 1000:1 gearboxes. This diagram does not apply to the HPCB versions, dual-shaft versions, or other gear ratios.

-

3D model of 1000:1 Micro Metal Gearmotors with extended motor shafts (precious metal brushes) (14MB step)

3D model of Pololu Micro Metal Gearmotors with 1000:1 gearboxes and extended motor shafts. This diagram does not apply to the HPCB versions, single-shaft versions, or other gear ratios.

-

3D model of HPCB Micro Metal Gearmotors (single-shaft, carbon brushes, not 1000:1) (11MB step)

3D model of high-power carbon brush (HPCB) Pololu Micro Metal Gearmotors. This diagram does not apply to precious metal brush (i.e. non-HPCB) versions, dual-shaft versions, or 1000:1 gear ratios.

-

3D model of HPCB Micro Metal Gearmotors with extended motor shafts (carbon brushes, not 1000:1) (11MB step)

3D model of high-power carbon brush (HPCB) Pololu Micro Metal Gearmotors. This diagram does not apply to precious metal brush (i.e. non-HPCB) versions, single-shaft versions, or 1000:1 gear ratios.

-

3D model of 1000:1 HPCB Micro Metal Gearmotors (single-shaft, carbon brushes) (14MB step)

3D model of high-power carbon brush (HPCB) Pololu Micro Metal Gearmotors with 1000:1 gearboxes. This diagram does not apply to precious metal brush (i.e. non-HPCB) versions, dual-shaft versions, or other gear ratios.

-

3D model of 1000:1 HPCB Micro Metal Gearmotors with extended motor shafts (carbon brushes) (14MB step)

3D model of high-power carbon brush (HPCB) Pololu Micro Metal Gearmotors with 1000:1 gearboxes and extended motor shafts. This diagram does not apply to precious metal brush (i.e. non-HPCB) versions, single-shaft versions, or other gear ratios.

This product is listed in:

Components & Parts>Motors>Metal GearmotorsComponents & Parts>Motors>Metal Gearmotors>Micro

Exact shipping can be calculated on the view cart page (no login required).

Products that weigh more than 0.5 KG may cost more than what's shown (for example, test equipment, machines, >500mL liquids, etc).

We deliver Australia-wide with these options (depends on the final destination - you can get a quote on the view cart page):

- $3+ for Stamped Mail (typically 10+ business days, not tracked, only available on selected small items)

- $7+ for Standard Post (typically 6+ business days, tracked)

- $11+ for Express Post (typically 2+ business days, tracked)

- Pickup - Free! Only available to customers who live in the Newcastle region (must order online and only pickup after we email to notify you the order is ready). Orders placed after 2PM may not be ready until the following business day.

Non-metro addresses in WA, NT, SA & TAS can take 2+ days in addition to the above information.

Some batteries (such as LiPo) can't be shipped by Air. During checkout, Express Post and International Methods will not be an option if you have that type of battery in your shopping cart.

International Orders - the following rates are for New Zealand and will vary for other countries:

- $12+ for Pack and Track (3+ days, tracked)

- $16+ for Express International (2-5 days, tracked)

If you order lots of gear, the postage amount will increase based on the weight of your order.

Our physical address (here's a PDF which includes other key business details):

40 Aruma Place

Cardiff

NSW, 2285

Australia

Take a look at our customer service page if you have other questions such as "do we do purchase orders" (yes!) or "are prices GST inclusive" (yes they are!). We're here to help - get in touch with us to talk shop.

Have a product question? We're here to help!

Videos

View AllGuides

Servos, Steppers or Solenoids? | Choosing an Actuator to Move Your Project

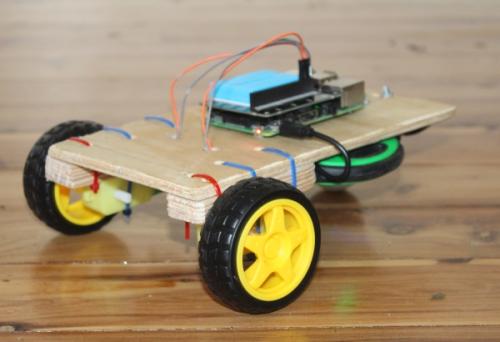

How To Control A Motor with the Raspberry Pi

The Maker Revolution

Motor Drivers vs. Motor Controllers

Projects

DIY Pi Buggy

Makers love reviews as much as you do, please follow this link to review the products you have purchased.

Product Comments