Ultimaker uses a very clever and intuitive system referred to as Print Cores to swap nozzles in and out quickly. There is a chip inside the Print Core which communicates information to the printer. Information such as nozzle type, diameter and potential material options are relayed which greatly improves workflow efficiency. If the nozzle is worn out in your Ultimaker Print Core the nozzle component is replaceable without having to buy a new Print Core.

Quick links for the contents of this guide is seen below.

There is no simple answer to what the best 3D printer nozzle is, it will always be a toss-up between what results you are trying to achieve and what materials are being used. 3D printer nozzle types and diameters may well have been the last thing on your mind, but I hope this guide will get you considering how they can help you.

If you've got any questions, queries or things to add to this topic please let us know your thoughts!

Reasons to Change Nozzles

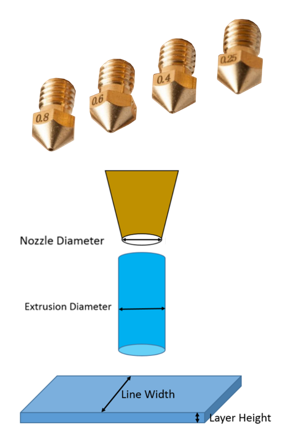

Extrusion width will influence several elements in a 3D print. For example, a larger diameter nozzle lays down wider perimeter wall lines. This means that it uses fewer perimeter lines than a smaller-diameter nozzle to print a wall of the same thickness. Below there is a model sliced two different times in Ultimaker Cura with different nozzle size employed, green is the perimeter wall (Ultimaker Cura is a free 3D printing slicing software, for more information check out Ultimaker Cura Overview). A nozzle with a larger diameter also allows prints to have an increased layer height. A good rule of thumb is layer height should be 80% of nozzle diameter, higher than this the layers will not adhere well. Combining these two effects leads to a noticeably shorter print time of solid models when larger diameter nozzles are used.

Smaller diameter nozzles will produce stronger components as they will better resemble in cross-section view a plastic injected component (0.1-0.2 mm layer height produce some of the strongest). Worth noting that the easiest way for a 3D printed component to break is by torque or shearing force across the printed layers, 3D printed layers are comparable to the wood grain in that regard.

Generally smaller diameter nozzles give higher detail at a longer print time, see an example of two version of the same print using different nozzles diameters in Ultimaker Cura. The smaller nozzle diameter will improve the horizontal plane resolution. Using a smaller nozzle permits a smaller layer height which will improve the vertical plane resolution, visible on the vertical sides of the models. The smaller diameter nozzle is also ideal for printing small models or text crisply as it will not leave small gaps between wall edges or lack important resolution. Supports will also be easier to remove and leave fewer artifacts.

There are many kinds of advantages that a change in nozzle type brings. The easiest place to start is to decide whether your nozzle type is one optimal for the purpose. Certain filaments are very abrasive and require a stronger nozzle material to ensure longer operating life of the printer, other filaments have different melting flow rates and prefer different nozzle hole profiles to ensure the best deposition.

Types of Ultimaker Print Cores

All Print Cores are interchangeable and almost all Ultimaker 3D printer products use the Print Core system. They allow quick changes between nozzles and materials creating a more time-efficient workflow environment. An accurate temperature reading is also gained from the Print Cores and they are reliable and durable components.

There are three distinct types of print cores produced by Ultimaker which have various sizes and support different materials, which you can see below.

•Type AA Build Core

Size 0.25mm, 0.4mm and 0.8mm Available

Best for printing all common Ultimaker Build materials and Ultimaker Breakaway material. Can also print an expansive portfolio worth of 3rd party materials! Not optimal for PVA and not the best nozzle to be used with a highly abrasive filament. For more knowledge on 3D printing material types, check out Ultimaker 3D Printer Material Guide.

•Type BB Support Core

Size 0.4mm and 0.8mm Available

For printing water-soluble support material (PVA). In dual-extrusion applications in tandem with engineering materials, it allows for consistent high-quality 3D prints. For more knowledge on dual-extruding in 3D printing check out Dual-Extrusion 3D Printing Guide.

•Type CC Extreme (Red) Build Core

Size 0.6mm Available

An abrasion-resistant print core used for printing composite materials such as carbon-fibre composite materials, metal composite materials, fibreglass composite materials and UV composite materials. Has a high wear-resistant ruby cone tip.

How to Change Ultimaker Print Cores

Almost all Ultimaker 3D printers use the Print Core system and as the system for swapping between them is very similar I have formed this encompassing guide. For Ultimaker 3 3D Printer the navigation through the wizard will be done using the rotate and click LED-backlit control wheel. For Ultimaker S3 3D Printer and Ultimaker S5 3D Printer, the navigation through the wizard will be done using the touch screen display. To change out your core follow the steps below.

1. Access the Change Print Core Wizard found in the Material Menu and select the Print Core you want to change.

2. Carefully open the Glass Doors. Make sure the print platform and print head is room temperature.

3. Flip the print head fan bracket down. It is attached by four neodymium magnets.

4. Using the Wizard click Confirm. The printer will then heat the nozzle and retract the currently installed material.

5. Once the nozzle is heated and filament retracted out of the print head the Wizard will prompt you.

6. Squeeze the levers of the currently installed Print Core and slide it out. Take care not to touch the contact points on the back of the print core and place it in a safe place.

7. With the new Print Core in hand, squeeze the levers together and slide it into the print head until you hear a click. By keeping it vertical while installing it should smoothly slide into place. It should be locked in and straight.

8. Carefully close the print head fan bracket.

9. The Print Core will automatically communicate to the Ultimaker 3D printer what type it is and ask in the Wizard if this is correct. Confirm if so.

10. Close the glass doors to the build platform. The nozzle will heat up and the filament will return to the end of the nozzle.

And just like that your new Print Core is now successfully installed, you can now go off and start 3D printing with it!