One of the first things you will do when you get your mitts on a new 3D printer is to install filament for it. Also, whenever your spool runs out of filament or when you want to change the colour/material being extruded you'll be running through this same method.

If you've got any questions, queries or things to add to this topic please let us know your thoughts!

Unloading Filament

By going through the following steps below you will unload a filament spool from your Ultimaker 3D Printer (now this is not required if your Ultimaker 3D printer is fresh out of the box as it will not have any filament installed. Jump to the Loading Filament section below if this is the case).

1. Start the Unload Wizard by selecting Unload button, located inside the Material menu of the Ultimaker 3D printer, accessed by either navigating using the LED Backlit Click Wheel or by pressing on the installed material icon using the Touchscreen (there you will find other related options available such as Load, Change or Select Type).

2. This Wizard will then make the print nozzle heat up to ensure the filament tip is melted and separate from the print head. While this is happening do not touch the print head as it is at a high temperature.

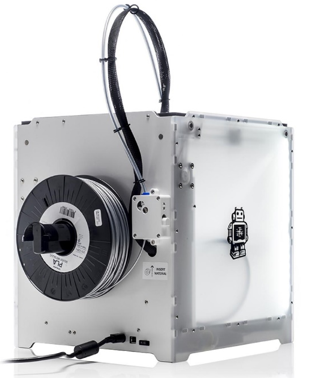

3. After less than 2 minutes the print nozzle temperature will be reached. The knurled wheel feeder, situated on the back of the Ultimaker 3D printer, will activate and go in reverse. This will withdraw the filament out of the system. To make your life easier take the time to help guide the filament back onto the spool by rotating the spool in tandem with feeder.

4. If the end of the filament has not completely come out of the feeder you can tug it delicately downwards to remove it.

5. Now with the filament completely out of the Bowden mechanism you can remove the connected spool and guard from the spool holder. The guard is a separate component which clips in on the end of the spool holder, retaining the spools, it can be seen in pictures on the right.

6. Holding these connected parts, you can unthread the old filament from the guide and then separate the guard from the spool. Best to now to slip the end of the old filament through one of the circumference holes on the spool so that the filament is not able to tangle.

Once you confirm on your Ultimaker the Wizard will be completed and you will have successfully unloaded the filament spool. Take the opportunity to make sure there are not small pieces of filament left in the feeder or Bowden system and that the nozzle is unobstructed.

Loading Filament

By going through the following steps below you will have loaded a new filament spool for your Ultimaker 3D Printer. If using an Ultimaker S5 3D Printer, Ultimaker S3 3D Printer or Ultimaker 3 3D Printer you can repeat this process to load another filament spool as all these machines are capable of dual-extrusion.

1. Grab your desired 3D filament spool which you want to install and remove all the packaging.

2. Pull off the guard component and unhook the filament spool. Slide the end of the filament through the guide hole located on the guard component.

3. Place the guard through the hub of the filament spool and click the two components together.

4. Now take this combination and place your new filament spool onto the spool hanger, located on the back of Ultimaker 3D Printers.

5. Having sorted above start the Wizard by selecting the Load button found under the Material menu of the Ultimaker 3D printer. This is accessed by either navigating using the LED Backlit Click Wheel or using the Touchscreen and then pressing on the empty material icon.

6. If your using an Ultimaker filament it will automatically detect which filament is being installed. It will ask for a confirmation that the material is the correct choice. If using a non-Ultimaker material, you can now manually select the material being used.

7. Now take the end of the filament and snip of the very tip of the new filament to give a clean edge (also worth making sure it is still threaded through the guide hole of the spool guard as its liable to fall out at this stage).

8. Then push the filament up into the corresponding knurled wheel feeder (some Ultimaker 3D printers will have two feeders on the back of the machine for dual-extrusion) which will be spinning at a very slow speed. Pushing the filament requires a little bit of force to get the Bowden feeder to take the filament. Once it is grabbed the clamping spring will lift and you will feel the resistance of it pulling through. Now it is important to wait until the filament has reached up past the knurled wheel feeder and into the Bowden tube, this can be seen on the right picture.

9. You now can press the LED Backlit Click Wheel or Touchscreen button to continue the Wizard. The Ultimaker 3D printer will ramp the speed of the feeder and run the filament quickly through the system. It will slow just before it reaches the print head and then creeps forward. The print head will then heat up taking no longer than 2 minutes.

10. Once the temperature is reached you should see material extruding out of the end of the print nozzle. This extruded material should come out as a straight line with no lumps or changes in diameter and it should extrude smoothly out the print nozzle. Also, make sure it has only the new colour coming through with the old colour being completely purged.

Once you confirm on your Ultimaker that material is being extruded correctly from the Print Core you will have successfully installed the filament spool! Keep in mind the print head will still be hot for a couple of minutes.

Troubleshooting

Signs of a blocked nozzle or incorrectly installed print head can be observed through the filament or the nozzle. The image below is a great reference for this. If your printer is extruding incorrectly take the time to clean out the print head. This can be done by giving the nozzle an acetone bath (if you have been using ABS or PLA), flossing the nozzle with a piece of clean filament or wire brush, using a hot gun or performing a cold pull. If these methods don't work, it could be time to replace the print head. If you want more related knowledge check out Ultimaker Print Nozzles Overview and Installation and another guide worth checking out Never Have Filament Grinding Again particularly the section on print nozzles.