★ Achievement unlocked - 3D Print "Glass" ★ Your friends will not believe the results but this guide will tell you all the secrets to have a 3D printed component which is beautifully transparent to the point of being able to perfectly see-through it.

This will go through the process of drastically improving your 3D printed part transparency. It will assume you already have a 3D printed components made from Polymaker Polysmooth Transparent Filament. This is a PVB (polyvinyl butyral) filament and if you have a filament made out of the same stuff then you too can get rad results using this technique. The magic of this process is occurring because PVB is soluble in alcohol. All the components seen in this guide are made from Polymaker Polysmooth Transparent Filament. The contents of this guide can be seen below.

- Before and After Mugshots

- Preparations (What You Need)

- Processing Procedure

- The Identity Parade

- Chronology

- Closing Statements

A great guide to refine and choose settings for your 3D printer to print transparent filament really well, particularly so they will undergo this process well, check out the guide Improving Results with Transparent Filaments. As always if you have any questions, queries or things to add please let us know your thoughts!

Before and After Mugshots

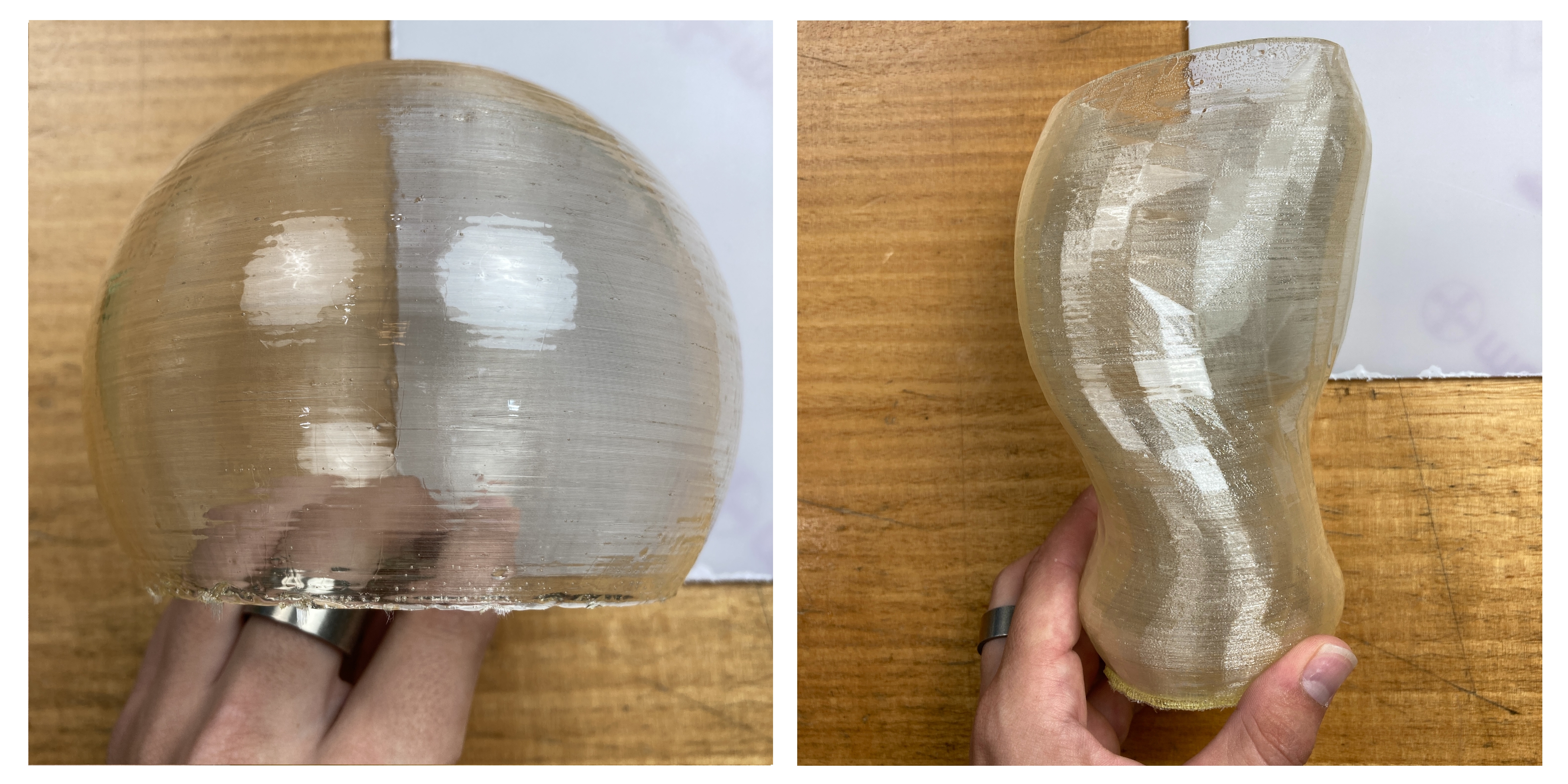

Most importantly is the before and after shot so you can see what this post-processing can do for components made from a 3D printer. If more time was spent on this process even better results would be possible. Below are four images with the before on the left and the after on the right. This was achieved after 10 days.

Preparations (What You Need)

Below is exactly what you will need to turn a PVB component into a see-through true glass-esque component.

- Poly Maker Polmaker PolySmooth Transparent

- Spray/Mist Bottle

- Isopropyl Alcohol

- Time and Patience

- Platform to let components dry on without much contact points

(3D printed PLA or ABS infill grids work well)

- 3D Printed Components that want to be see-through

(For best results use thin-walled objects which you can easily get to all surfaces of, components like a vase or a jug work well)

Processing Procedure

Polysmooth transparent is a PVB material. PVB (polyvinyl butyral) is soluble in alcohol. This means after a liberal and repeated sprays/mists of alcohol over the model you can hide all the layer lines and smooth out the final piece. It is similar to how ABS is soluble to acetone and you can smooth out the layer lines with acetone. Polishers work but the best results can come from using a mist spray. PVB is normally used as a bonding layer in laminated safety glass. Make sure to do this process in a well-ventilated area as well as utilising both gloves and masks.

So the workflow is as follows.

- Spray the inside and outside of the thin-walled object with a liberal amount of Isopropyl alcohol using the mist spray bottle.

- If it is a container swish the built-up liquid inside it and then after getting all the surfaces moist empty out as much as you can

- Place on top of a 3D printed platform or infill made out of a material which will not dissolve in contact with isopropyl alcohol with the container facing downwards

- Do not touch with fingers at this stage as it will mark the surface

- Repeat later on in the day when all the isopropyl has dissolved

- Repeat this process for a week and a half (9 days) or until satisfied with the result

- Let Components have two days to rest up to prevent smudging what will be soft and pliable material until they dry completely.

By going through and doing this you will end up with a beautiful component that will trick people into thinking it was made from glass. People will also believe that the component has always had a clean, sin-free soul.

The Identity Parade

Below are the individuals in custody which went through due process to rid them of their unevenness and lack of good sparkle. These are the models that underwent the processing procedure and all had different character traits when they mandatorily volunteered to go through this course of betterment. They have each been assigned suitable names as you can see in the picture below.

Details about each individual piece are as follows.

Thin Vase - Printed using vase mode with a single wall thickness

Thin Globe - Printed using vase mode with a single wall thickness

Thick Vase - Printed with a wall thickness of two lines with a very thin air space between the two lines.

Thick Globe - Printed with 1mm wall thickness with no space between the lines. Also, a 115% flow was used to ensure no air bubbles or gaps inside the material and PVA Support material was used which was dissolved away using water.

Chronology

Below is Thin Vase and Thin Globe at multiple stages through this recovery program. You can see how quickly the transparency improves and also how the improvement starts to plateau off after Day 7 when you compare it to the final pieces which were completed on Day 9 and then photographed two days later. Continuing the processing for more days with these thin wall objects would end up leaving you with an unusable object that is too weak to hold instead of further improving the transparency. Call it a weakness of character.

Below are the Thin Vase and Thin Globe completed demonstrating how far improved it has come by being enrolled in this program.

Below this is the Thick Globe and the Thick Vase. The thick globe is turning out nicely however still requires a couple more days of processing. Thick Vase has a really interesting character now as all external surfaces are really smooth however the internal air layer which I intentionally created has not been affected by the processing. This has meant certain sections have become transparent (where the angle of the vase was too steep so there was no air gap between the two PVB lines and sections where it is this glossy opaque almost gold surface. Proper interesting and further processing will not help improve transparency for this particular suspect.

Closing Statement

Best results will come when you are creating good 3D prints that will enable this process to occur most effectively so check out the guide Improving Results with Transparent Filaments. This process has worked most effectively with the individuals with the thinnest (single layer) walls. It is pretty remarkable the transparency change that has occurred over the stages. Definitely use a drying platform which has very few contact points to the material as all contact points will mark the surface. If you use a flat surface the PVB will end up melting and connecting the drying surface. Hopefully, this has given you all the tools you need to replicate this process at your Makerverse. Big thanks go to 3D Print General who has great knowledge on this particular material both in regards to printing and post-processing. SLA and DLP Printing offer methods to create components that look like glass too, that will be a future nugget of content. Until then I leave you below with a transparent 3D print done on a Creality LD-002R and Transparent Resin by my co-worker and forum superstar Owen, definitely an excellent print!