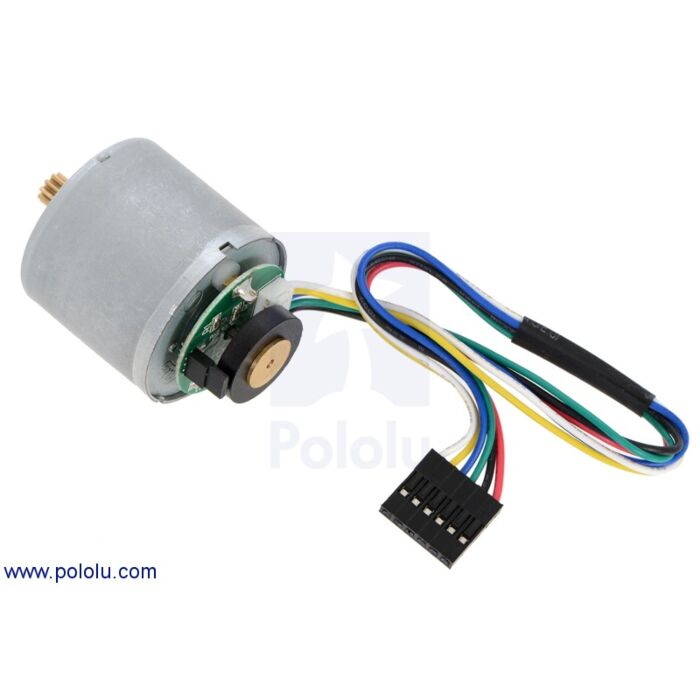

Motor with 64 CPR Encoder for 37D mm Metal Gearmotors (No Gearbox)

Retired Product

Search for an alternative |

Overview

This motor with integrated 64 CPR (counts per revolution) quadrature encoder is intended as a replacement motor and encoder for Pololu's 37D mm metal gearmotors. The 2mm output shaft has a non-removable pinion gear that works with all of Pololu's 37D mm gearmotor gearboxes. Note that we do not sell the 37D mm gearboxes separately, but if you have a gearmotor with a damaged motor or encoder (or if you want to effectively add an encoder to a version without an encoder), you can transfer the gearbox to this replacement motor.

The motor has a diameter of 34.5 mm (1.36 in) and a length of approximately 44 mm (1.7 in) from the top of the motor can to the bottom of the encoder. The top of the motor has six mounting holes evenly spaced around the outer edge threaded for M2.5 screws. These mounting holes form a regular hexagon, with the center of each hole located 13 mm from the center of the output shaft.. The mounting holes have a depth of approximately 3.5 mm.

Pinion Gear Specs

- Metric with module m = 0.5

- Number of teeth: 10

- Face thickness: 4 mm

- Pressure angle: 20°

- Gear position: 9 mm from top of motor to top of gear

Gearmotor Options

You will typically want to combine this motor with a gearbox to give it a more appropriate combination of torque and speed (without a gearbox, it offers very high speed with very low torque). Pololu's 37D mm line of metal gearmotors consist of this motor combined with different gearboxes. We do not carry the gearboxes by themselves, so unless you are looking at this as a replacement motor for a compatible gearbox you already have, Pololu strongly recommend you consider getting a preassembled gearmotor with the gear ratio that best suits your project requirements.

| Gear Ratio | No-Load Speed @ 12 V | Stall Torque @ 12 V | Stall Current @ 12 V |  With Encoder |  Without Encoder |

|---|---|---|---|---|---|

| 1:1 | 11,000 RPM | 5 oz-in | 5 A | motor without gearbox | |

| 19:1 | 500 RPM | 84 oz-in | 5 A | 37Dx52L mm | 37Dx52L mm |

| 30:1 | 350 RPM | 110 oz-in | 5 A | 37Dx52L mm | 37Dx52L mm |

| 50:1 | 200 RPM | 170 oz-in | 5 A | 37Dx54L mm | 37Dx54L mm |

| 70:1 | 150 RPM | 200 oz-in | 5 A | 37Dx54L mm | 37Dx54L mm |

| 100:1 | 100 RPM | 220 oz-in | 5 A | 37Dx57L mm | 37Dx57L mm |

| 131:1 | 80 RPM | 250 oz-in | 5 A | 37Dx57L mm | 37Dx57L mm |

These motors are intended for use at 12 V, though the motor can begin rotating at voltages as low as 1 V.

|

| 37D mm metal gearmotor with 64 CPR encoder. |

|---|

Using the Encoder

A two-channel Hall effect encoder is used to sense the rotation of a magnetic disk on a rear protrusion of the motor shaft. The quadrature encoder provides a resolution of 64 counts per revolution of the motor shaft when counting both edges of both channels. To compute the counts per revolution of the gearbox output, multiply the gear ratio by 64. The motor/encoder has six color-coded, 11" (28 cm) leads terminated by a 1×6 female header with a 0.1″ pitch, as shown in the main product picture. This header works with standard 0.1″ male headers and Pololu's male jumper and precrimped wires. If this header is not convenient for your application, you can pull the crimped wires out of the header or cut the header off. The following table describes the wire functions:

| Color | Function |

|---|---|

| Red | motor power (connects to one motor terminal) |

| Black | motor power (connects to the other motor terminal) |

| Green | encoder GND |

| Blue | encoder Vcc (3.5 – 20 V) |

| Yellow | encoder A output |

| White | encoder B output |

The Hall sensor requires an input voltage, Vcc, between 3.5 and 20 V and draws a maximum of 10 mA. The A and B outputs are square waves from 0 V to Vcc approximately 90° out of phase. The frequency of the transitions tells you the speed of the motor, and the order of the transitions tells you the direction. The following oscilloscope capture shows the A and B (yellow and white) encoder outputs using a motor voltage of 12 V and a Hall sensor Vcc of 5 V:

|

| Encoder A and B outputs for 37D mm metal gearmotor with 64 CPR encoder (motor running at 12 V). |

|---|

By counting both the rising and falling edges of both the A and B outputs, it is possible to get 64 counts per revolution of the motor shaft. Using just a single edge of one channel results in 16 counts per revolution of the motor shaft, so the frequency of the A output in the above oscilloscope capture is 16 times the motor rotation frequency.

Selecting the Right Gearmotor

Pololu offer a wide selection of metal gearmotors that offer different combinations of speed and torque. Pololu's metal gearmotor comparison table can help you find the motor that best meets your project’s requirements.

|

| Some of the Pololu metal gearmotors. |

|---|

Exact shipping can be calculated on the view cart page (no login required).

Products that weigh more than 0.5 KG may cost more than what's shown (for example, test equipment, machines, >500mL liquids, etc).

We deliver Australia-wide with these options (depends on the final destination - you can get a quote on the view cart page):

- $3+ for Stamped Mail (typically 10+ business days, not tracked, only available on selected small items)

- $7+ for Standard Post (typically 6+ business days, tracked)

- $11+ for Express Post (typically 2+ business days, tracked)

- Pickup - Free! Only available to customers who live in the Newcastle region (must order online and only pickup after we email to notify you the order is ready). Orders placed after 2PM may not be ready until the following business day.

Non-metro addresses in WA, NT, SA & TAS can take 2+ days in addition to the above information.

Some batteries (such as LiPo) can't be shipped by Air. During checkout, Express Post and International Methods will not be an option if you have that type of battery in your shopping cart.

International Orders - the following rates are for New Zealand and will vary for other countries:

- $12+ for Pack and Track (3+ days, tracked)

- $16+ for Express International (2-5 days, tracked)

If you order lots of gear, the postage amount will increase based on the weight of your order.

Our physical address (here's a PDF which includes other key business details):

40 Aruma Place

Cardiff

NSW, 2285

Australia

Take a look at our customer service page if you have other questions such as "do we do purchase orders" (yes!) or "are prices GST inclusive" (yes they are!). We're here to help - get in touch with us to talk shop.

Have a product question? We're here to help!

Guides

The Maker Revolution

Projects

Pico-Dog Motion Activated Audio Alarm

WaveJumper: Music Sample Slicer on a Breadboard

PiicoDev Ecosystem In Fritzing

Makers love reviews as much as you do, please follow this link to review the products you have purchased.

Product Comments