Magnetic Encoder Pair Kit for 20D mm Metal Gearmotors, 20 CPR, 2.7-18V

In stock, ships same business day if ordered before 2PM

Fastest delivery: Tomorrow*

Disclaimer:

For next-day delivery, the shipping address must

be in the AusPost next-day network, eParcel Express must be selected, and the order must be placed

before 2PM AEST Mon-Thurs excluding NSW Public Holidays. Orders may be delayed due to AusPost

pickup timings and order verifications. eParcel Express is typically a 1-day service within the

AusPost next-day network, though it is sometimes 2+ days.

Quantity Discounts:

- 10+ $13.44 (exc GST)

- 25+ $13.02 (exc GST)

This kit includes two dual-channel Hall effect sensor boards and two 10-pole magnetic discs that can be used to add quadrature encoding to two 20D mm metal gearmotors with extended back shafts (motors are not included with this kit). The encoder board senses the rotation of the magnetic disc and provides a resolution of 20 counts per revolution of the motor shaft when counting both edges of both channels. To compute the counts per revolution of the gearbox output shaft, multiply the gear ratio by 20. (We also have a 6-pole magnetic disc available separately that can work with this encoder to provide 12 counts per revolution of the motor shaft.)

|

This compact encoder solution fits within the 20 mm diameter cross section of the rear of the motors on three of the four sides. The fourth side of the encoder has the signal and power connections, and it extends 3 mm past flat edge of the motor. The assembly does not extend past the end of the extended motor shaft, which protrudes 6 mm beyond the back of the motor.

|

|

Note: This sensor system is intended for users comfortable with the physical encoder installation. It only works with 20D mm meta gearmotors that have extended motor shafts.

Pinout and installation

The encoder board is designed to be soldered directly to the back of the motor, with the back shaft of the motor protruding through the hole in the middle of the circuit board. One way to achieve good alignment between the board and the motor is to tack down the board to one motor pin and to solder the other pin only when the board is flat and well aligned. Be careful to avoid prolonged heating of the motor pins, which could deform the motor case or brushes. Once the board is soldered down to the two terminals, the motor leads are connected to the M1 and M2 pads along the edge of the board; the remaining four pads are used to power the sensors and access the two quadrature outputs:

|

|

The sensors are powered through the VCC and GND pins. VCC can be 2.7 V to 18 V, and the quadrature outputs A and B are digital signals that are either driven low (0 V) by the sensors or pulled to VCC through 10 kO pull-up resistors, depending on the applied magnetic field. The sensors’ comparators have built-in hysteresis, which prevents spurious signals in cases where the motor stops near a transition point.

|

Encoder A and B outputs of a magnetic encoder on a 6V 20D mm metal gearmotor running at 6V. |

|---|

The board’s six pads have a 0.1" (2.54 mm) pitch, so Pololu are compatible with common 0.1" connectors, or you can just solder individual wires directly to the board.

Once the board is soldered to the motor, the magnetic encoder disc can be pushed onto the motor shaft. One easy way to accomplish this is to press the motor onto the disc while it is sitting on a flat surface, pushing until the shaft makes contact with that surface. From here, Pololu recommend further pushing the disc a little closer to the PCB (by approximately 1 mm) to help ensure a strong signal and good performance. The exact position doesn’t matter; just make sure not to push it so close that the magnet is rubbing against the sensors.

|

Push the magnetic disc onto the motor shaft so the shaft protrudes approximately 1 mm past the disc. |

|---|

Schematic diagram

|

This schematic is also available as a downloadable pdf (54k pdf).

People often buy this product together with:

| Pololu Universal Aluminum Mounting Hub for 4mm Shaft, #4-40 Holes (2-Pack) |

| Pololu 20D mm Metal Gearmotor Bracket Pair |

| Magnetic Encoder Pair Kit for Micro Metal Gearmotors, 12 CPR, 2.7-18V |

Dimensions

| Size: | 20 mm × 16.5 mm |

|---|---|

| Weight: | 2.4 g1 |

General specifications

| Minimum operating voltage: | 2.7 V |

|---|---|

| Maximum operating voltage: | 18 V |

| Encoder resolution: | 20 CPR2 |

Identifying markings

| PCB dev codes: | enc04a |

|---|---|

| Other PCB markings: | 0J9719 |

Notes:

- 1

- Weight of full set. Each encoder board weighs ~0.6 g and each magnet disc weighs ~0.6 g.

- 2

- When counting both edges of both channels.

File downloads

-

Magnetic Encoder for 20D mm Metal Gearmotors schematic diagram (54k pdf)

-

Dimension diagram of the Magnetic Encoder Pair Kit for 20D mm Metal Gearmotors, 20 CPR, 2.7-18V (178k pdf)

-

Drill guide for the enc04a encoder PCB (35k dxf)

This DXF drawing shows the locations of all of the board’s holes.

-

3D models of Magnetic Encoder Pair Kit for 20D mm Metal Gearmotors, 20 CPR, 2.7-18V (481k zip)

This file contains 3D models (in the step file format) of the components for the Magnetic Encoder Pair Kit for 20D mm Metal Gearmotors, 20 CPR, 2.7-18V.

Exact shipping can be calculated on the view cart page (no login required).

Products that weigh more than 0.5 KG may cost more than what's shown (for example, test equipment, machines, >500mL liquids, etc).

We deliver Australia-wide with these options (depends on the final destination - you can get a quote on the view cart page):

- $3+ for Stamped Mail (typically 10+ business days, not tracked, only available on selected small items)

- $7+ for Standard Post (typically 6+ business days, tracked)

- $11+ for Express Post (typically 2+ business days, tracked)

- Pickup - Free! Only available to customers who live in the Newcastle region (must order online and only pickup after we email to notify you the order is ready). Orders placed after 2PM may not be ready until the following business day.

Non-metro addresses in WA, NT, SA & TAS can take 2+ days in addition to the above information.

Some batteries (such as LiPo) can't be shipped by Air. During checkout, Express Post and International Methods will not be an option if you have that type of battery in your shopping cart.

International Orders - the following rates are for New Zealand and will vary for other countries:

- $12+ for Pack and Track (3+ days, tracked)

- $16+ for Express International (2-5 days, tracked)

If you order lots of gear, the postage amount will increase based on the weight of your order.

Our physical address (here's a PDF which includes other key business details):

Unit 18, 132 Garden Grove Parade

Adamstown

NSW, 2289

Australia

Take a look at our customer service page if you have other questions such as "do we do purchase orders" (yes!) or "are prices GST inclusive" (yes they are!). We're here to help - get in touch with us to talk shop.

Have a product question? We're here to help!

Guides

The Maker Revolution

Projects

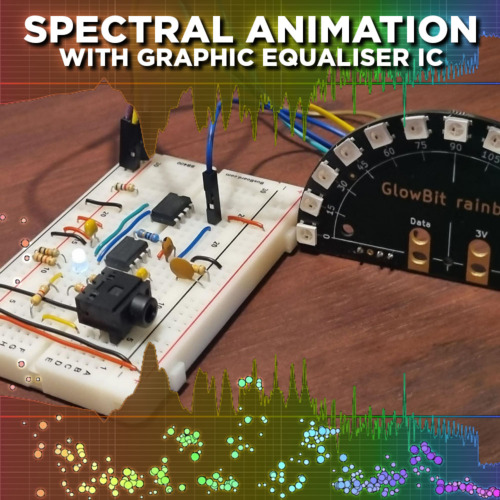

Spectral Animations with a DIY MSGEQ7 I2C Device

VisionSphere: Camera Motion Detection for Raspberry Pi

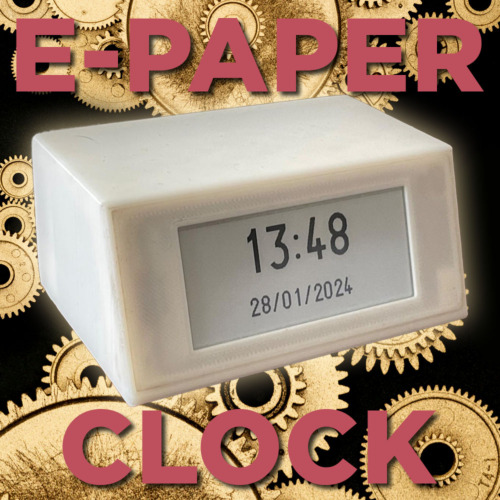

Arduino E-Paper Clock

Makers love reviews as much as you do, please follow this link to review the products you have purchased.

Product Comments