Feeder gear slippage can be caused by several different factors and when it occurs it can require some troubleshooting to correctly identify the culprit. If a print starts off working well but then fails midway through it is indicative that the problem has to do with feeder gear slipping. To ensure the filament feeds perfectly and to best troubleshoot when experiencing filament grinding on your 3D printer the contents of this guide has been separated into the sections seen below.

- 3D Printer Filament

- Material Feeder

- Print Nozzle

- Utilizing the Most Current Firmware

- Slicing Software Settings

- Impacts from Surrounding Environment

- Associated Hardware - Bowden Tubing, Teflon Insulator, Cooling Fans and Stepper Motor of Feeder

- Crazy Fixes

Beautiful 3D prints need the filament to be driven by the extruding system correctly allowing it to travel through the heated nozzle and onto the build platform. If your running into issues hopefully this guide will help you sleuth out the solution like a modern-day Hercule Poirot! As always if you have got any questions, queries or things you'd like to see added please let us know your thoughts!

3D Printer Filament

Often one of the main perpetrators when it comes to filament grinding is the filament. Start off this inspection by making sure you're using premium filament materials. Premium filament is manufactured to very high tolerances ensuring the filament is both round and of a constant diameter. Premium filament will have fewer contaminants and less variability in mechanical properties. These factors contribute to improved reliability and accuracy, helping lower filament grinding. Premium filament will result in a better quality print result and as an added bonus releases fewer odours when melted.

Next, make sure the filament is the same diameter at the one required by the printer. Most Ultimaker 3D printers run using 2.85mm to 3mm diameters. If the filament size is outside the 3D printers boundaries it can very easily cause grinding. Some 3D printer material is extremely hygroscopic meaning that they absorb moisture from the air. Absorbing water swells the material, creating diameter differences and changes to mechanical properties such as melt flow rate. This increases the potential for filament grinding so make sure to use fresh material whenever possible and store hygroscopic material appropriately. It is worth noting you can remove water from hygroscopic 3D printer filament but it requires care to do correctly, perhaps a future guide.

Sometimes stock filament spool is wound up very tight direct from the factory which can cause filament grinding. Smooth unspooling will be hindered as the tightly spooled filament will fight against the correct operation of the 3D printer. The spooled material will constantly pull back from the feeder whilst the feeder pushes forward. This conflict will cause the filament to grind as it is caught in this tug of war yanked back and forth. The simple solution is to loosen up the filament reel itself. Shake and bristle the filament in the spool to relax the strain and loosen the material. Also, an obvious but easily overlooked problem is the filament overlapping itself on the spool. It is not uncommon to have the filament loop under itself when you remove it from the printer for storage. It can be hard to see but if neglected it will halt the smooth operation of the print.

Material Feeder

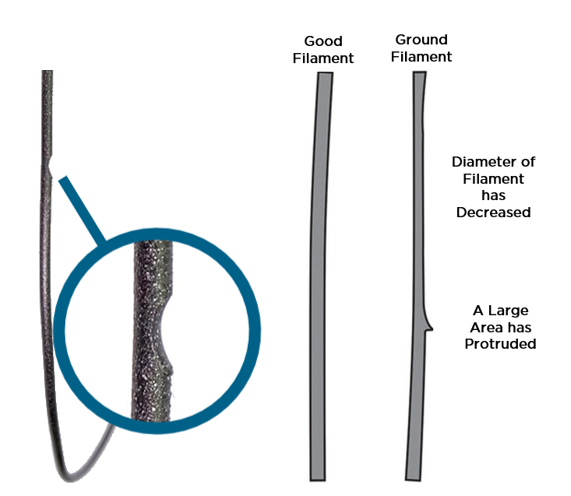

Many extruders use a drive gear with sharp knurled teeth that bite into the filament. This allows the extruder to move the filament back and forth. A principal suspect to investigate when your 3D printer is undergoing grinding is this feeder. Evidence of this 3D printing crime will be all over the knurled feeding wheels of the extruder. An internal inspection will reveal that the knurled feeder wheels are dirty with plastic debris, dust or potentially even rust. Clean off all these surfaces as slipping will continue to occur if not maintained.

These feeders typically include an adjustment that changes how hard the drive gear is pressed into the filament. On Ultimaker 3D printers this is a screw on the top of the Bowden feeder. For these printers, materials such as PLA, ABS and Tough PLA should all operate effectively with the middle tension setting on the Ultimaker Bowden feeder. This indicator dial is located on the vertical side of the Bowden feeder, middle tension setting is when the indicator knob is in the middle. Lower tensions should be used for soft and delicate filament. Furthermore, it is important to realise loosening the feeder will not necessarily be the instant fix to grinding. Loosening the tension increases the potential for the filament to slip which can also lead to grinding.

Next, check for mechanical issues by evaluating the pressure that the knurled gear is driving the filament. The Bowden extruder on Ultimaker machines can push filament very hard. After making sure the knurled gear is clean go through the process of loading new material. A great guide to help you with this is Loading and Unloading Filament for Ultimaker 3D Printers. Once up to the stage of manually pushing the new filament into the activated feeder (Step 8 of Loading Filament in the above guide) and it has reached significantly into the Bowden tube you can now test the strength of the feeder. Grab the filament and apply around 5kg force to wrestle against the feeder. You should not be able to pull the filament out of the system and the feeder should still move forward. Increase the tension if the filament slips out of the system.

Print Nozzle

All 3D printers utilize print nozzles to heat and extrude material onto the build plate. The nozzle diameter directly affects the extrusion diameter of each line in a 3D print and directly determines layer height. They are crucial to successful prints and should be under the magnifying glass if grinding is occurring on your printer. The most common standard nozzle sizes for most 3D printers is 0.4mm. It makes for a great all-rounder, a good middle ground between speed and quality. However, it does not take much for it to become partially or fully blocked due to the tiny exit hole. Also, as the filament is abrasive the print nozzle is a wearing part and could be at the end of their lifespan. Check out Ultimaker Print Nozzles Overview and Installation to learn more.

Any manner of contaminant can cause blockages. They can come from the outside environment or from impurities in the filament. Blockages also occur if the filament is burnt when the print nozzle is set too hot or if there is the residue of the previous filament which has a higher melting point than what you are currently employing. Blockages cause higher stress on the 3D printing system as it tries to extrude the filament. This will eventually lead to filament grinding.

Furthermore, when it comes to nozzles it is important that the build platform is calibrated correctly. If the build platform is too close to the tip of the print nozzle it can create undue pressure on the feeder as it takes more work to get the material out. Here is a guide for the Ultimaker 3D Printer Build Platform Calibration. Also, settings can be altered inside your Slicing program to directly address the initial squish. Check out Printing Perfect First Layer Ultimaker Cura guide to learn more.

Putting on your deerstalker, if the extruder motor is pushing a thin amount of material out of the nozzle or if the extruded material curls heavily the second it comes out of the nozzle, it is indicative of a blocked nozzle. See the image below for examples. Also, blockages can sometimes be seen visually. Below are several nozzle cleaning procedures. The cleansing methods get progressively more extreme the lower you go.

1. Pushing filament manually into the extruder. Whilst the 3D printer is attempting to extrude filament (ergo as the extruder motor is operating and the print nozzle is at temperature) also manually push the filament into the feeder with your hands. This added force in many situations will be enough to overcome the blockage, eject it and return the print nozzle to normal operation.

2. Reload the material into the 3D printer. This allows you to snip off and remove the tip of the damaged/melted filament that was right next to the nozzle when the material is unloaded. By retracting the material it may also pull out contaminants blocking the nozzle. An excellent reference for this is Loading and Unloading Filament for Ultimaker 3D Printers. You may need to manually apply some added force if the filament does not retract normally.

3. Utilising a portion of wire or needle, raise the temperature of the print nozzle and dig inside the print nozzle. A wire made from copper or another type of soft metal would be best to limit scratching the print nozzle. Acupuncture needles also work very well. Be very careful doing this as it may take some cycles and the print nozzle will be very hot. If you have been printing with PLA raise the temperature to 230°. If you have been printing with other materials with higher melting points raise the temperature to 260°. Now you are not necessarily pulling the whole blockage out of the nozzle but prodding it repeatedly to break up the contaminations into smaller parts. Test the print nozzle by running normal operation and with a bit of luck, the now smaller parts will be flushed out.

4. Utilising Hot Pull and Cold Pull (Atomic) methods to clean the print nozzle. Both these methods involve unloading the filament material and removing the plastic tubing that guides the filament to the print head. Now for both methods raise the temperature of the print nozzle. If you have been printing with PLA raise the temperature to 230°. If you have been printing with ABS or other materials with higher melting points raise the temperature to 260°. Snip off a segment of filament which is a hand length long. Once print nozzle temperature has been reached pushed this segment of filament directly into the back of the print nozzle. Applying pressure on the filament, you will hopefully see some extrusion out of the nozzle but it does not matter if you do not. If you see extrusion keep pushing to drive some contaminate out through the nozzle. After 10 seconds of pushing the filament in pull it out quickly and sharply. This is a Hot Pull. Snip off the tip and repeat this process multiple times until the tip of the filament comes out clean and shaped like the interior of the nozzle. A Cold Pull involves lowering the temperature of the print head whilst continually pushing the filament in into the print head. For PLA lower the print head temperature to 90°. For ABS or other higher melting points lower the print head temperature to 160°. Once the print head has reached this lower temperature pull it out quickly and sharply. Similarly, snip off the tip and repeat this process multiple times. A Cold Pull puts a lot of strain on 3D printing hardware and should be done only after consideration. Test the cleansed print nozzle by running normal operation.

5. Remove the print nozzle from the 3D printer. Then utilise a hot air gun to heat the print nozzle and make use of a wire or needle to prod out blockages. Follow a similar procedure applying the same tools and technique as Method 3. This gives you the advantage of cleaning the nozzle from both sides but do take care as the print nozzle will be quite hot.

6. Remove the print nozzle from the 3D printer and immerse the part into acetone or other aggressive solvents. This will eat away at the contaminant after a few hours. Using a wire or needle the prod out any potential chemically weakened blockages should result in a perfectly squeaky-clean print nozzle. Follow a similar procedure applying the same tools and technique as Method 3. This process will take the most time out of them all but will yield the greatest final result.

Utilizing the Most Current Firmware

A subtle and simple fix for filament grinding can boil down to updating the firmware of your 3D printer to the most current up to date version. A detail that even Adrian Monk could miss, the firmware is a specific class of computer software that provides the low-level control for your 3D printer's specific hardware.

Download location for the newest Ultimaker 3D Printer Firmware can be seen below.

- Ultimaker 3D Printer Firmware

Slicing Software Settings

Slicing software is essential to get your 3D printer to produce components. Put simply slicing software allows you to turn the computer file of your design into a recipe for a 3D printer to follow. However, a bad recipe can sometimes lead to filament grinding. If all the hardware has been inspected (and should be operational) it is time to put the recipe under the spotlight.

Start by considering the printing speed setting. The default print speed for most systems is around 45mm/s. To lower the chance of filament grinding slow this value down. Next, other settings worth checking in the recipe is ensuring the flow rate is 100% and that the temperature of the print nozzle is correctly set for the particular material type.

Other adjustments to make in your slicing software if your encountering filament grinding would be settings related to retraction. Retraction is when the feeder pulls the filament away from the print nozzle. The purpose of retraction is to prevent filament oozing out of the nozzle and depositing on the model in wrong places. If you have too many retractions occurring over the same location of filament you can potentially grind it to dust. A good starting point to minimise this negative effect of retraction would be to reduce the retraction speed by 70% in your slicing program. This will lower the acceleration rate of the filament and minimise stresses on the filament.

Another method to minimise filament grinding is achieved by utilising more combing in the print recipie. Combing causes the print head to move inside the perimeter of the part to get to new deposition location instead of travelling across voids. By encouraging more combing there will be a lower amount of retractions in a print. A good place to learn more is Printing Perfect First Layers - Ultimaker Cura particularly the section on combing.

Impacts from Surrounding Environment

All 3D printers like stable, well ventilated, cool-climates. They operate at their best when there is no radical wind gusts or changes in ambient air temperatures. If in hot climates with a very high ambient temperature or in an excessively humid environment it will lead to issues with 3D printers, one of which is filament grinding. Definitely take the time to check out the environment specifications of your particular 3D printer as this habitually judged red herring can actually be the cunning culprit!

Associated Hardware

Diving deeper into the 3D printer interrogation, if after checking off previous possibilities, there are a number of potential hardware suspects to grill under cross-examination which could be the origins of filament grinding.

- Bowden Tubing. This is a plastic tube that guides filament to the heated print head. Over time it will accumulate contaminations inside of it. These contaminations cause significant resistance to the smooth travel of the filament. Blockages will occur if particularly bad. This leads to feeder slippage and filament grinding. By removing the tubing from the 3D printer you can test it. Whilst someone holds the Bowden tubing in the U shape that it would form when installed on the 3D printer, attempt to slide filament through the tubing. Clean or replace the tubing if the effort to move the filament is too high.

On an Ultimaker 2+ 3D Printer the filament will be driven with 5 kg of force by the feeder. The feeder on other Ultimaker 3D printers will drive the filament with even more force. Ultimaker 3D printers use PFA Bowden tubing however worth considering are PTFE tubing. Filament will slide through PTFE significantly better than PFA tubing of the same diameter size.

- Teflon Insulator. This is a small section of Teflon tube which is located just before the print head. Located in the throat of the 3D printer it can often be neglected. Teflon is very resistant to high temperatures but over time it will gradually become carbonised. This creates a smaller diameter for the filament to travel through. By replacing this component it has the potential to ease pressure on the system and thus stop filament grinding.

- Cooling Fans. These are fans attached around and directed at the tip of the print nozzle. They are employed to cool the filament after it has been extruded. They also have a habit of working themself loose from their power connections. This is mainly due to vibrations. It can be hard to realise that one fan out of four is not working if you are not looking for it. Fans can also wear out. Keep all fans fully operational to prevent filament grinding.

- Stepper Motor of Feeder. A very tough customer to sleuth out, the stepper motor of the feeder can get very hot. This heat travels along the shaft to the knurled gears that drive the filament. This has the potential to get so hot that the filament softens. PLA is the most common material to have this occur due to the comparatively low melting point. As soon as the material softens the filament will be ground up by the feeder. This will be a serious problem when the printer is situated in an environment which has a high ambient temperature. Potential solutions involve cooling the stepper motor directly with a cool fan or moving the 3D printer to a new colder locale.

Crazy Fixes

You've tried everything above! The 3D printer is still grinding filament! I've got two different crazy ideas to fix it.

- Loosen the bolts ever so slightly that hold the Bowden feeder onto the back of the 3D printer (I'm talking half a revolution). This will let the Bowden feeder move around ever so slightly like suspension. This suspension may just help.

- The Vaeder V-Struder is an extruder which does away with knurled gears and instead uses a belt to push the filament through the system. Therefore you'll be left with a stronger grip filament and no more grinding! I have some swell pictures of it attached. This will require some serious commitment to get it successfully operational. Check it out here - Vaeder V-Struder