The realm of 3D printers is currently the forefront of new technology. The capabilities of these machines are under relentless progression determined hugely by the technologies available and needs from the community. Reliability, accuracy and the eternal ‘does it print in more colours?’ are often some of the most common community desires. One of the best ways that all these needs are delivered is through dual-extrusion printing.

Dual-extrusion printing is the process of 3D printing with multiple filaments in a single print, which when it first arrived ushered in vast new potentials. You could now print composite materials, produce with ease multicoloured components and have drastically advanced support structure options at your fingertips.

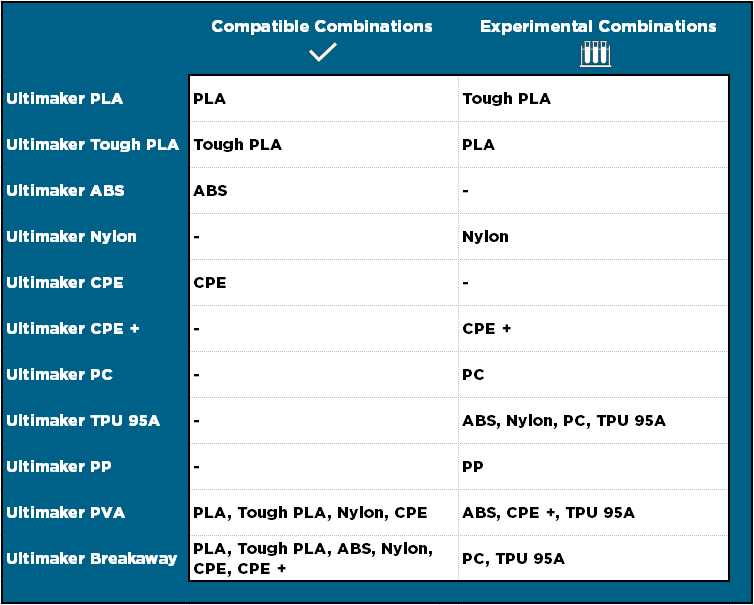

Now specific materials can bond well with some materials but not well with others. As dual-extrusion printing often occurs with different filament materials it is worthwhile to understand and know these relationships between them. 3D printers also have limits on what materials they can print, an example of this can be seen in Ultimaker 3D Printer Material Compatibility Guide, and furthermore what materials combinations they can operate with.

So I’m here to give the lay the land! In this guide we’ll explore:

- Material Combinations in Dual-Extrusion Printing for Ultimaker

- Overview of Dual-Extrusion Printing

- Improved Capability of Supports using Dual-Extrusion

- Purge Towers and Ooze Shields

As you can learn in the Ultimaker 3D Printer Material Guide there is a huge range of filament materials available on the market with varying properties and characteristics. Interestingly when printing different materials together you will have formed a composite material. This composite will have its own unique physical properties, a blend of both the ingredients and construction.

If you've got any questions, queries or things to add to this topic please let us know your thoughts!

Ultimaker Material Combinations in Dual-Extrusion Printing

As I’ve said before not all 3D printing machines are made equal and this is especially true when comparing printers with or without dual-extrusion. For Ultimaker printers this dual-extrusion capability is found on Ultimaker S5 3D Printer and Ultimaker S3 3D Printer as standard. Below is a chart in relation to Ultimaker dual-extrusion printing, displaying compatible and experimental material combinations.

All Ultimaker materials have print profiles specifically tested and developed for use on Ultimaker 3D printers set up in Ultimaker Cura (the open-source 3D printer slicing software made by Ultimaker). This means once you’ve decided on a couple of parameters in Ultimaker Cura and used compatible combinations you’ll be ready to print using dual-extrusion! Experimental material combinations will likely require more effort by the user to print successfully.

Worth noting Ultimaker 3D printers has an open filament system, meaning third-party materials can be used, so above is by no means a complete picture of all possible material combinations. 3D printing filaments have a wide range of properties and successful prints employing multiple materials will become harder the more extreme the material differences. Printing two completely different materials is normally not good engineering practise as bonding between them will often be weak and inevitably produces poor prints. For the best success, it is crucial to know the interactions between different materials when utilizing dual-extrusion heads.

Overview of Dual-Extrusion Printing

The rest of this article will be spent laying clear the advantages and thus the reasons why you should consider dual-extrusion printing in your future ventures.

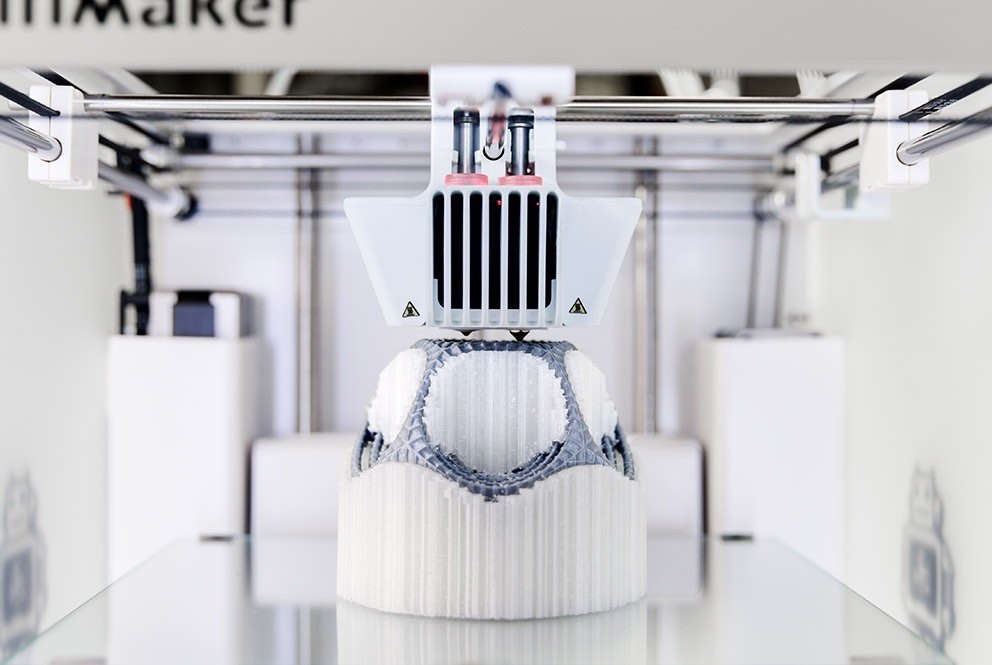

Dual-extrusion printing is the process of 3D printing with multiple filaments in a single print. This means your printer will have a nozzle or nozzles capable of depositing filament from two separate material spools one by one. Dual-extrusion opens a world of composite materials, multicoloured prints and greater capabilities for supports. This hugely expands the possibilities for your own 3D printed components.

Dual-extrusion capabilities are found on Ultimaker S5 3D Printer and Ultimaker S3 3D Printer as stock standard. Also, other Ultimaker 3D printers can have this ability mounted and installed by a capable user but experimentation would be required to run optimally. Ultimaker S5 and S3 Printers have dual-extrusion heads with two nozzles where each filament is deposited through its own nozzle respectively. Worth noting there are 3D printers on the market which can print with multiple colours of the same material from a single nozzle. Also, there are multicoloured materials available where the colour changes along the length of the filament which is another method to get some vibrancy into your models.

Improved Capability of Supports using Dual-Extrusion

Ultimaker PVA Material is commonly used as a support in dual-extrusion prints because it will produce the greatest printing stability compared to all other materials. This material also allows support structures to be printed in enclosed cavities. This is all possible because PVA material dissolves in water. So once the printing is completed just by immersing entire prints in water the entire support materials will be removed. This simple post-processing procedure means support structures can be placed more densely and in places otherwise unreachable. PVA material won’t cause external artefacts and will leave the surface quality of the 3D print completely undamaged.

Ultimaker Breakaway Material excels best when employed in operations where the final model is water sensitive or speed of manufacture is critical. Breakaway material in a dual-extrusion operation is useful as it can be snap removed better than all other materials. Due to this, support structures can be placed closer to the final model enabling better stability during the printing operation. Breakaway material will also least impact the surface finish when compared against other water-proof materials.

Purge Towers and Ooze Shields

These are utilized in the printing operation as a method to clean excess material off the nozzles by having a surface for them to rub against. They will be utilized every time the filaments are swapped between as once material is halted the heated unused nozzle will ooze out a small amount of stringy excess filament. Without either a purge tower or an ooze shield, you’ll end up with stringy hair-like filament covering your desired component. These stringy filaments will cause errors in your print, require post-processing and possibly fail the print entirely. Purge towers and ooze shields are available as an option in Ultimaker Cura and require only a couple of user-inputted parameters to give the best result. These methods are an added complexity and cost filament, but their use guarantees an enhanced overall print quality.

Take the time to check out the guide all about Purge Towers and Ooze Shield if you want more information on specific settings to implement.